Description

https://www.transformermachines.com/Assembling-Fixture.html

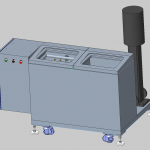

The horizontal assembly fixture serves as a valuable aid in the assembly of radiator panel assemblies to header pipes. After the panels are placed in a rack fixture at the automated stacking machine, this rack is then inserted into the horizontal assembly fixture. One end of the fixture is manually adjusted to accommodate the overall assembly length, while the other end functions as a hydraulic press, securely positioning and holding the entire assembly for tack welding.

For the welding of panels to the header pipe after assembly, MIG welders are required. These mobile units are equipped with approximately 200 – 250A current and feature a special long nozzle to reach in between panels effectively. It is the customer's responsibility to develop welding fixtures according to their requirements and safety of their welders. Certified welders are strongly recommended for this welding process.

![[CAS: 97540-22-2] S-Adenosyl-L-methionine disulfate tosylate [CAS: 97540-22-2] S-Adenosyl-L-methionine disulfate tosylate](https://tradedowntown.com/wp-content/uploads/2024/11/cd6c8c0df42abcb1111e127453b9bcc9.webp)

![[GN:05003] Gemigliptin Impurity 3 (DP-IMP-3) [GN:05003] Gemigliptin Impurity 3 (DP-IMP-3)](https://tradedowntown.com/wp-content/uploads/2024/08/fbf45b7349c129991cecc4970bd37ee8-150x150.png)