Description

Wuxi Yushun Metallurgy Technology Co., Ltd is a comprehensive enterprise integrating scientific research and development, engineering design, system integration, equipment installation, sales service, we serve numerous iron and steel enterprises domestic and overseas. Main projects include design and manufacture of technology, machinery, fluid, electric control for steel-making equipment, steel rolling equipment and steel deep processing.

The design of the dust collecting cover of the electric furnace dust collector has various forms. The more mature ones are: semi-closed collecting cover, closed cover, side suction cover, roof cover and so on. And the semi-closed cover does not affect the smelting operation, low energy consumption, strong and durable, good capture effect is also long-term adhere to the development and full promotion.

We have professional from related area, experienced engineering technicians from design and research institute, iron and steel enterprise, we can joint research and development with domestic excellent enterprises with good technology and rich practical experience in metallurgical industry, customize high, intermediate and low grades configurations of production line or single equipment, provide overall design for smelting, continuous casting and steel rolling to meet the production requirements of low power consumption and high efficient, we also can contract turnkey project.

Wuxi Yushun Metallurgy Technology Co., Ltd takes the concepts of “customer first, technology-based” and meets the demands of customer including design, manufacture, installation, pre-sales guidance and after-sales service.

Choosing Wuxi Yushun Metallurgy Technology Co., Ltd as partner means choosing trust and guarantee, we can help your career development, let’s cooperate and create the future together. Sincerely welcome your presence and guidance.

What is intermediate frequency furnace trap cover for sale?

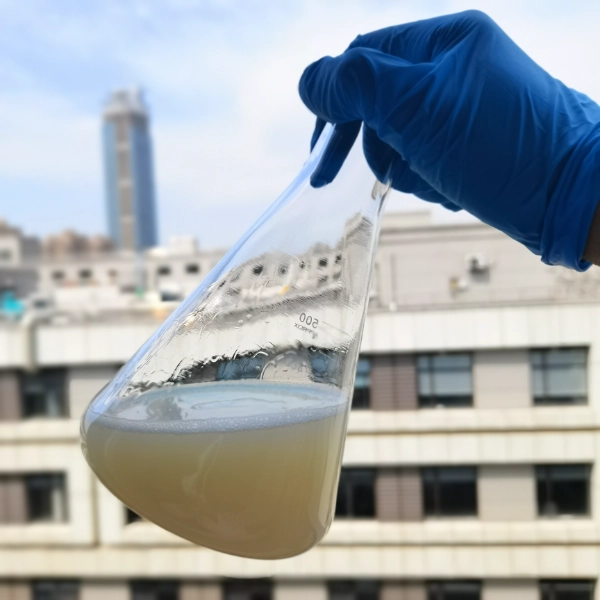

An intermediate frequency furnace trap cover is a removable device installed near the furnace opening. It acts as a filter that prevents any impurities from entering the furnace during metal melting and casting.

The intermediate frequency furnace trap cover has two main components; the upper part and lower part. The upper portion consists of an insulated cover with an opening to allow for charging materials, while the lower half contains a removable filter made up of refractory bricks or ceramic fiber material.

This device is specifically designed to trap any unwanted material such as slag, dust particles, sand grains, and other contaminants from entering into the molten metal. By doing so, it helps in producing high-quality metals by reducing impurities in the final product.

Apart from this primary function, intermediate frequency furnace trap covers are also known to increase productivity since less time is spent on cleaning out unwanted materials. Moreover, they reduce energy consumption by improving heat retention within the system.

Features of intermediate frequency furnace trap cover:

1. Enhanced Safety:

The trap cover of an intermediate frequency furnace provides an additional layer of safety by preventing accidental contact with the molten metal or hot gases inside the furnace.

2. Heat Insulation:

The trap cover is designed to have excellent heat insulation properties, minimizing heat loss from the furnace and improving energy efficiency.

3. Easy Access and Maintenance:

The trap cover is designed for easy access to the furnace for maintenance and cleaning purposes. It can be easily opened and closed, allowing for quick inspections and repairs.

4. Contamination Prevention:

The trap cover helps prevent contaminants, such as dust, dirt, and foreign objects, from entering the furnace, ensuring the purity of the molten metal and maintaining the quality of the final product.

5. Temperature Control:

The trap cover helps regulate the temperature inside the furnace by providing insulation and preventing heat loss, allowing for precise temperature control during the melting process.

6. Durability and Longevity:

The trap cover is made from high-quality materials that are resistant to heat, corrosion, and wear, ensuring its durability and longevity in the demanding environment of the intermediate frequency furnace.

7. Safety Interlocks:

Some trap covers are equipped with safety interlocks, which prevent the cover from being opened while the furnace is in operation, further enhancing the safety of the furnace operators.

8. Customizable Design:

Trap covers can be customized to fit the specific requirements of different types and sizes of intermediate frequency furnaces, ensuring a perfect fit and optimal performance.

9. Noise Reduction:

The trap cover can help reduce the noise generated by the furnace operation, creating a more comfortable working environment for the operators.

10. Improved Efficiency:

By effectively trapping and containing the heat within the furnace, the trap cover helps improve the overall efficiency of the melting process, reducing energy consumption and operating costs.

Advantages of intermediate frequency furnace trap cover supply:

1. Enhanced Safety:

The use of trap covers in intermediate frequency furnaces provides an additional layer of safety by preventing accidental contact with the molten metal or hot gases. This helps in reducing the risk of burns and injuries for the operators.

2. Improved Energy Efficiency:

Trap covers help in minimizing heat loss during the melting process by creating a barrier between the molten metal and the surrounding environment. This results in improved energy efficiency and reduced energy consumption, leading to cost savings.

3. Reduced Oxidation:

By covering the molten metal, trap covers help in reducing the exposure to oxygen, which can cause oxidation. This leads to better quality metal with reduced impurities, resulting in improved product quality.

4. Increased Melting Efficiency:

Trap covers aid in maintaining a stable temperature within the furnace, allowing for more efficient melting of the metal. This helps in achieving faster melting times and higher production rates.

5. Minimized Heat Radiation:

The use of trap covers helps in reducing heat radiation from the furnace, resulting in a cooler working environment for the operators. This can improve comfort levels and reduce the need for additional cooling systems.

6. Extended Refractory Life:

Trap covers act as a protective layer for the refractory lining of the furnace, reducing its exposure to the harsh conditions of the melting process. This can extend the lifespan of the refractory materials, leading to cost savings on maintenance and replacement.

7. Improved Metal Quality:

Trap covers help in preventing the entry of contaminants, such as dust or debris, into the molten metal. This leads to improved metal quality with reduced impurities, resulting in better end products.

8. Versatility:

Trap covers can be designed to fit different furnace sizes and configurations, making them suitable for a wide range of applications in various industries.

9. Easy Installation and Maintenance:

Trap covers are typically designed for easy installation and removal, allowing for quick maintenance and cleaning of the furnace. This helps in minimizing downtime and maximizing productivity.

10. Environmental Benefits:

The use of trap covers in intermediate frequency furnaces can contribute to environmental sustainability by reducing energy consumption, minimizing emissions, and improving overall process efficiency.

The importance of intermediate frequency furnace trap cover

This product is designed to prevent debris and foreign objects from entering your furnace, ensuring its optimal performance and longevity. Made with high-quality materials, it is durable and easy to install, providing you with peace of mind and cost-effective maintenance.

Yushun produces various types of intermediate frequency furnace trap cover,as a furnace bag dust collector manufacturer and supplier, and the steel rolling equipment we supply is well received.

Related news of intermediate frequency furnace trap cover

The role of intermediate frequency furnace trap cover

Features and application of intermediate frequency furnace trap cover

![[GN:05003] Gemigliptin Impurity 3 (DP-IMP-3) [GN:05003] Gemigliptin Impurity 3 (DP-IMP-3)](https://tradedowntown.com/wp-content/uploads/2024/08/fbf45b7349c129991cecc4970bd37ee8-150x150.png)