Description

https://www.reizthailand.com/Stamping-Parts-SAF-Series-B.html

Made of low alloy high strength steel, with high precision, high production efficiency and good product consistency

The stamping materials must have certain stamping performance, so it is easy to obtain high-precision and high-precision stamping parts, which is convenient for production and processing. At the same time, the final deformation degree and limit deformation degree of one stamping process are the same. It should be large enough to increase productivity. The precondition is that the loss of stamping materials should be low and worn in precision stamping parts and precision stamping dies.

Precision Stamping part is a forming and processing method of applying external force to plate, strip, pipe and profile by press and die to produce plastic deformation or separation, so as to obtain the workpiece (stamping part) with required shape and size. Stamping and forging belong to plastic processing (or pressure processing), collectively known as forging. The billets for stamping are mainly hot-rolled and cold-rolled steel plates and strips.

characteristic:

(1) the stamping parts are manufactured by stamping on the premise of low material consumption. The parts have light weight and good stiffness. After plastic deformation, the internal structure of the metal is improved to improve the strength of the stamping parts.

(2) the stamping parts have high dimensional accuracy, uniform size with the module, and good interchangeability. General assembly and use requirements can be met without further machining.

⑶ during the stamping process, because the surface of the material is not damaged, the stamping parts have good surface quality and smooth and beautiful appearance, which provides convenient conditions for surface painting, electroplating, phosphating and other surface treatment

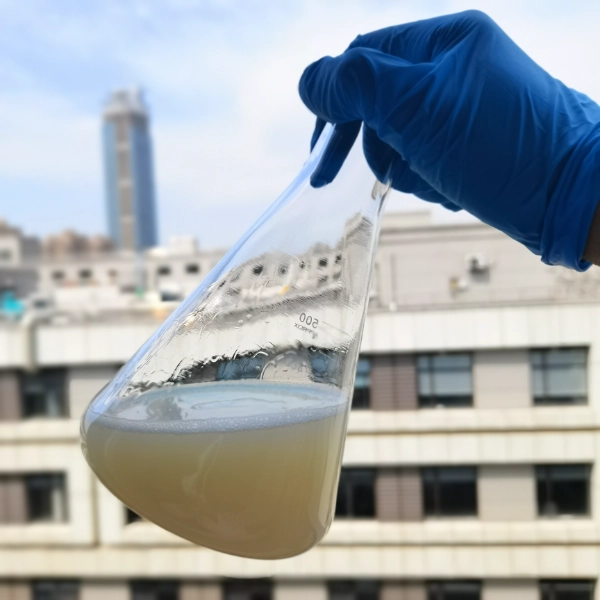

![6-Benzyl 2-tert-butyl 2,6,9-triazaspiro[4.5]decane-2,6-dicarboxylate 6-Benzyl 2-tert-butyl 2,6,9-triazaspiro[4.5]decane-2,6-dicarboxylate](https://tradedowntown.com/wp-content/uploads/2025/12/8d6b55309bc609cef2a5cd8cecfaed8b-150x150.png)

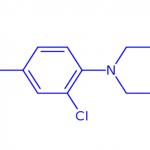

![[GN:05003] Gemigliptin Impurity 3 (DP-IMP-3) [GN:05003] Gemigliptin Impurity 3 (DP-IMP-3)](https://tradedowntown.com/wp-content/uploads/2024/08/fbf45b7349c129991cecc4970bd37ee8-150x150.png)