Description

Suzhou Jwell Machinery Co., Ltd.is an important development strategic center

and manufacturing base of Jinwei Machinery. It is located in Chengxiang

Industrial Park, Taicang, Suzhou, and is 30 minutes' drive from Shanghai

Hongqiao Airport. It covers an area of 20 hectares, with an indoor area of

120000 square meters. It is equipped with advanced CNC machining base for parts

and standard assembly workshop. With more than 1000 employees, it has a

high-quality design and development team and an experienced team of mechanical

and electrical commissioning engineers.

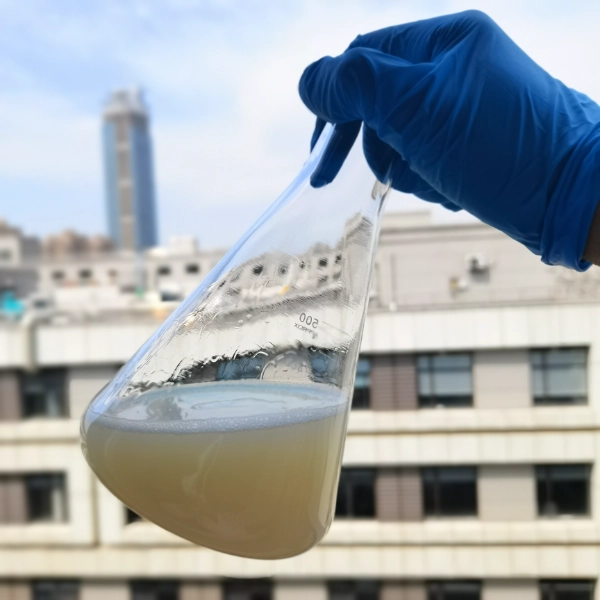

The company focuses on plastic pipe and sheet film extrusion equipment

manufacturing and various professional technical services, and carefully

manufactures plastic extrusion equipment that meets the needs of global users,

of which foreign trade exports account for more than 75%. Strict design, strict

standardized manufacturing process and perfect after-sales service guarantee

system provide users with efficient, energy-saving and high-quality production

line equipment and considerate services.

Contact whatsapp: 138 1703 9977 / 139 1685 8896 / 139 1887 6278 / 134 7257 0215 / 158 0622 6900

Email: salbn@jwell.cn

Summary

Performance & Advantages

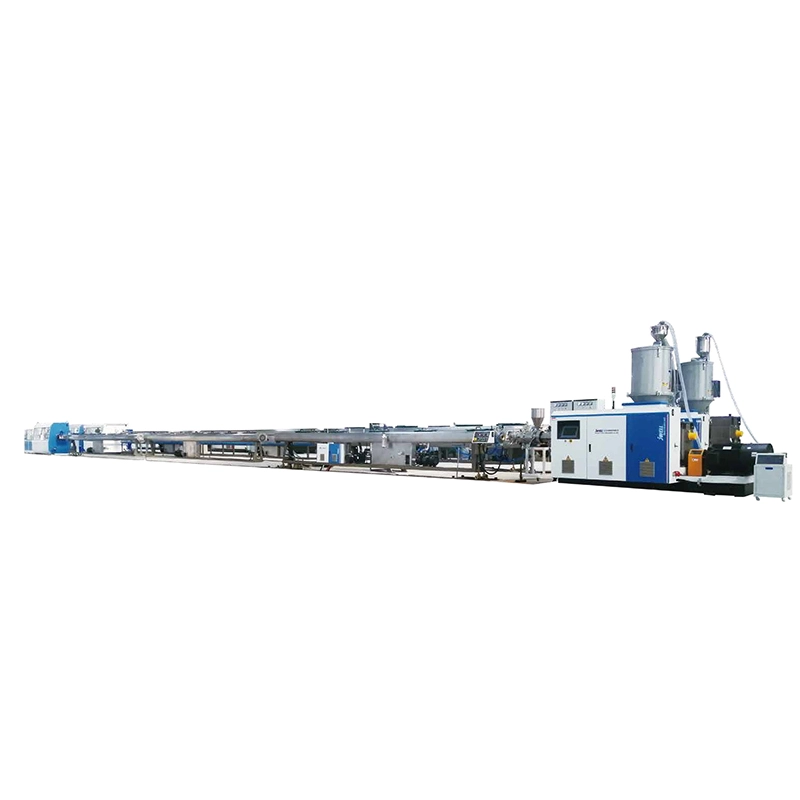

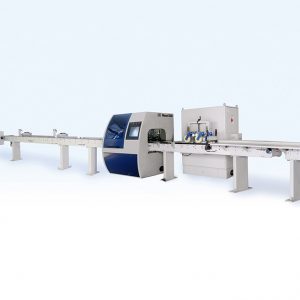

Our company's latest research and development of energy-saving high-speed production

line, suitable for high-speed polyolefin pipe extrusion. 35% energy saving and 1x increase in production efficiency.

Specifically designed 38-40 L/D screw structure and the feeding slot barrel make the melt extrusion and plasticizing effects

greatly improved. High-torque, high-strength gearboxes ensure stable operation of the equipment.

Extrusion molds and sizing sleeves adopt the most advanced design structure. The PLC variable frequency control vacuum

tank, servo-driven multi-track tractor, and high-speed chipless cutter are equipped with a meter weight control system. The

pipe extrusion weight is more accurate.

Main Technical Parameters

| Model | Pipe Spec (mm) | Extruder | Main Power(kw) | Output (kg/h) |

| JWPEG-H63 | Ø16-Ø63 | JWS-H 60/40 | 90 | 400 |

| JWPEG-H110 | Ø20-Ø110 | JWS-H 60/40 | 110 | 450 |

| JWPEG-H160 | Ø50-Ø160 | JWS-H 75/38 | 132 | 500 |

| JWPEG-H250 | Ø75-Ø250 | JWS-H 75/38 | 132 | 550 |

| JWPEG-H315 | Ø110-Ø315 | JWS-H 75/38 | 160 | 650 |

| JWPEG-H450 | Ø160-Ø450 | JWS-H 90/38 | 250 | 950 |

| JWPEG-H630 | Ø315-Ø630 | JWS-H 90/38 | 280 | 1050 |

| Note:The specifications are subject to change without prior notice. | ||||

High-speed energy-saving HDPE solid wall pipe extrusion line for sale

The high-speed HDPE solid wall pipe extrusion line is a state-of-the-art technology used for the production of high-density polyethylene (HDPE) pipes. This process involves melting and shaping plastic into desired forms by forcing it through a die using pressure.

This innovative system utilizes advanced techniques to produce HDPE solid wall pipes with greater speed, accuracy, and energy efficiency than traditional methods. The line operates at much higher speeds while reducing material waste, making it an environmentally friendly option that can save businesses significant costs in materials and labor.

One of the key features of this technology is its ability to produce smooth, uniform pipes with precise dimensions. By eliminating inconsistencies and defects in the final product, manufacturers can ensure maximum durability and longevity for their products.

The HDPE solid wall pipe extrusion line offers numerous benefits over traditional manufacturing methods. Its innovative design provides faster production times, seamless quality control measures, reduced material waste, improved precision in product dimensions – all leading to increased profitability for companies who adopt this new approach.

Features of high-speed energy-saving HDPE solid wall pipe extrusion line supply

The HDPE solid wall pipe extrusion line offers superior features for efficient and reliable production. With advanced technology and precision engineering, this line ensures high production speeds while saving energy. Enjoy seamless pipe extrusion, enhanced output, consistent quality, and reduced operational costs, making it an ideal solution for your industrial needs.

As a high-speed energy-saving hdpe solid wall pipe extrusion line supplier, Jwell Machinery enjoys a high reputation at home and abroad for the various models of plastic pipe extrusion machines we supply.

Related news of high-speed hdpe solid wall pipe extrusion line

The features of Jwell solid wall pipe extrusion line

Advantages of high-speed hdpe solid wall pipe extrusion line

![[GN:05003] Gemigliptin Impurity 3 (DP-IMP-3) [GN:05003] Gemigliptin Impurity 3 (DP-IMP-3)](https://tradedowntown.com/wp-content/uploads/2024/08/fbf45b7349c129991cecc4970bd37ee8-150x150.png)