Description

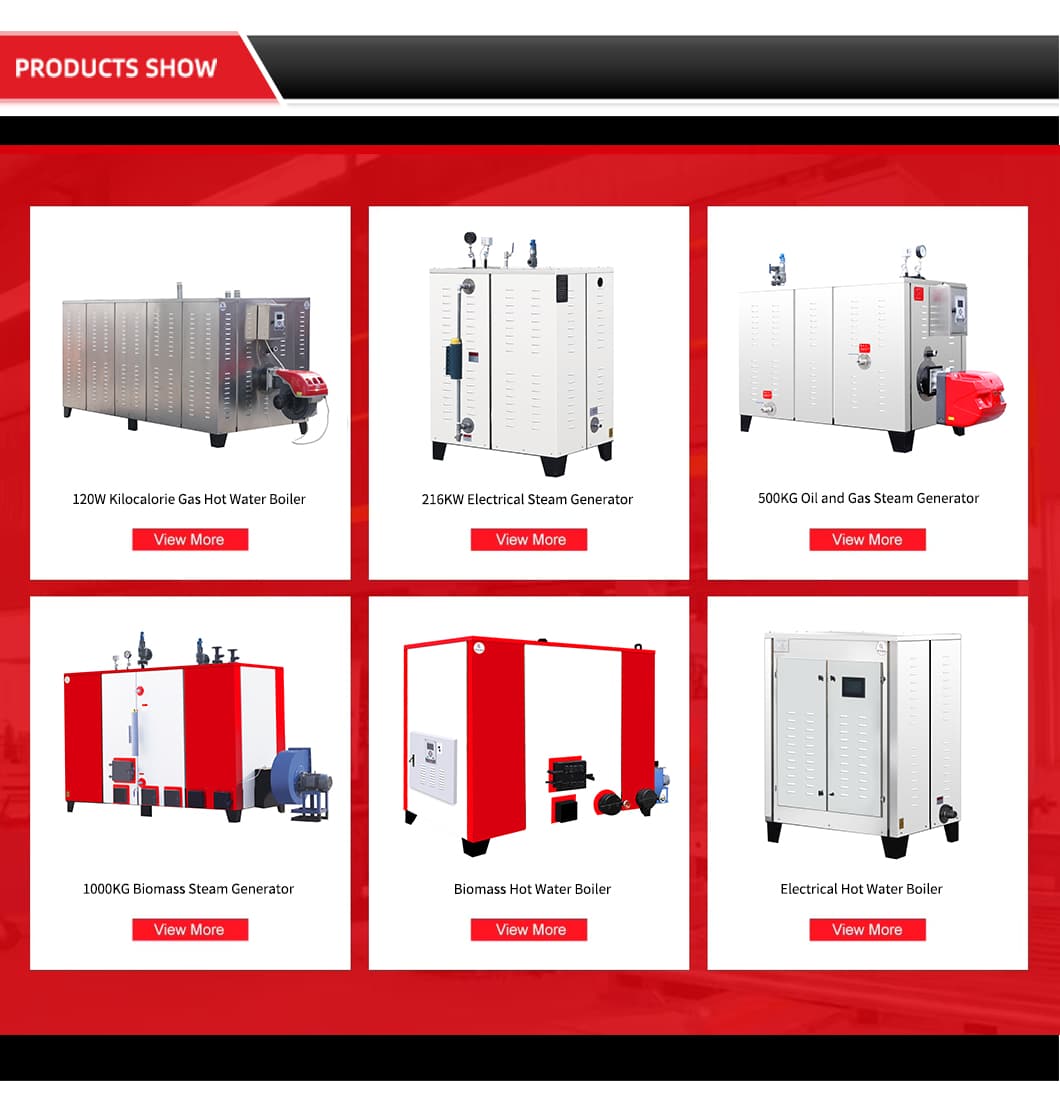

Technical Advantages of Guihong Biomass Steam Generators:

1.No Permit Required: The product is a through-flow multi-tube heat-storage steam generator, with a single (tube) body water capacity of less than 30L. It is easy to use and operate.

2.Intelligent and Convenient Operation: One-key start for fully automatic operation, automatic fuel feeding, automatic ignition, automatic water replenishment system, high/low pressure automatic start-stop, adjustable power, and automatic pressure transmitter frequency control technology.

3.Energy-saving and Environmental Protection: Uses biomass granules (wood, coal) as fuel. Equipped with combustion assistance systems, automatic frequency control for draft and induced draft fans, and secondary oxygen supply for complete combustion. Low smoke and dust emissions, no ash blockage, and minimal coking. The combustion chamber features a suspended vaporization device, with the inner shell undergoing 12-stage recirculation combustion, large heat transfer area, and a thermal efficiency of over 90%. Certified by national authorities, all indicators are qualified and awarded as an Energy-saving and Environmentally Friendly Promoted Product.

4.Quality Assurance: Manufactured in strict accordance with national boiler inspection regulations and the GB/T 19001 idt ISO 9001:2015 quality management system. Professionally welded by certified mid-to-senior-level electric welders and technicians, with rigorous 3x pressure testing (compared to the national standard of 1.5x). All indicators must pass inspection before factory release.

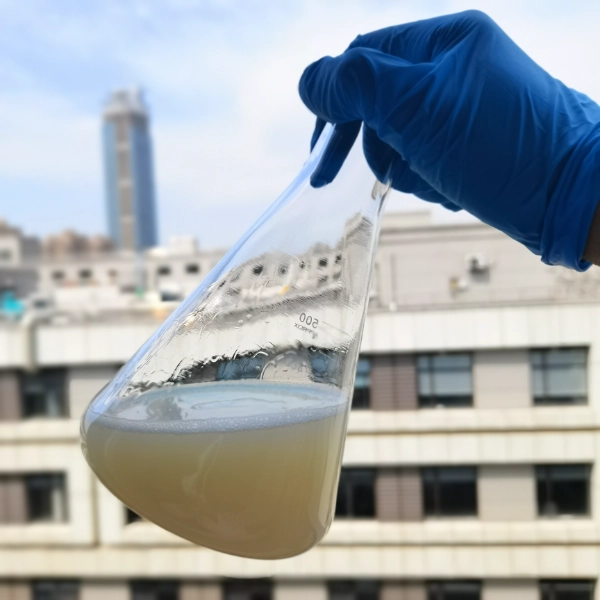

5.Fast Steam Generation: Short steam generation time, with steam available in 5 minutes under normal combustion conditions. The steam is dry, water-free, and abundant.

6.Multiple Safety Protections: Electronic overpressure protection, mechanical safety valve, low-water protection, leakage protection, and overheat protection.

7.Modern Aesthetics: The design incorporates corporate culture elements, with an attractive appearance. Integrated mechanical and electrical design for easy installation by general electricians and plumbers.

8.Wide Application Fields: Suitable for industries requiring hot water and steam, including cleaning and disinfection, electroplating and acid washing, chemical adhesives, cement products, catering and laundry, bathing and heating, color printing and packaging, plastic foam, hotels and restaurants, office buildings, tofu production, reactors, slaughterhouses, drying, oil fields, breeding, clothing, breweries, and food processing.

SWZQ-GH10-200 basic information :

Heat Output Power(Kcal):120000

Thermal Efficiency (%):>85

Chimney Diameter (mm):140

Fuel Storage Capacity (Kg):140

Voltage (V):220

Blower Power (Kw):0.25

Multistage Pump Power (Kw):0.75

Total Machine Weight (Kg):880

Saturated evaporation rate at 0.01 MPa, 75% > (temperature difference compensation at 0.7 MPa):200kg/333m3

Heat Output Power (equivalent to electrical kW):144

Saturated Steam Pressure and Temperature (ºC):0.0-0.7MPa(100-165ºC)

Is water treatment required:Treated boiler feedwater or reverse osmosis water must be used

Maximum Water Capacity per (Tube) Body (L):<10

Number of Steel Tubes (pieces):51

Length of Steel Tubes (m):45

Number and Specification of Water Level Gauges (Units * mm):1*218

Safety Valve Orifice Size (DN mm):15

Feedwater pipe diameter (DN mm):15

Blowdown Pipe Diameter (DN mm):25

Maximum particulate fuel consumption (kg/h):30

Average particulate fuel consumption (kg/h):15

Diesel automatic igniter (units):1

Total input electrical power (kW):2.5

Induced draft fan power (kW):0.75

Number of Feeding Motors and Power (kW):1*0.3

Dimensions (main unit + fan) – Length, Width, Height (cm):(180+70)*64*185

Product basic information of the same series:

| Product model | SWZQ-GH10-400 | SWZQ-GH10-500 | SWZQ-GH10-600 | SWZQ-GH10-800 |

| Heat Output Power(kcal) | 240000 | 300000 | 360000 | 480000 |

| Heat Output Power (equivalent to electrical kW) | 288 | 360 | 432 | 576 |

| Saturated steam pressure temperature(ºC) | 0-0.7MPa(100-165ºC) | 0-0.7MPa(100-165ºC) | 0-0.7MPa(100-165ºC) | 0-0.7MPa(100-165ºC) |

| Maximum Water Capacity per (Tube) Body (L) | <29 | <29 | <29 | <29 |

| Number of Steel Tubes (pieces) | 56 | 70 | 100 | 128 |

| Thermal efficiency (%) | >85 | >85 | >85 | >85 |

| Number and Specification of Water Level Gauges (Units * mm) | 1*218 | 1*218 | 2*280 | 2*280 |

| Steam outlet pipe(DNmm) | 20 | 20 | 25 | 32 |

| Safety Valve Orifice Size (DN mm) | 20 | 20 | 25 | 32 |

| Blowdown Pipe Diameter (DN mm) | 20 | 20 | 25/32 | 25/32 |

| Chimney diameter(mm) | 140 | 140 | 165 | 180 |

| Fuel Storage Capacity (kg) | 160 | 180 | 230 | 300 |

| Number of Feeding Motors and Power (kW) | 1*0.3 | 1*0.3 | 1*0.3 | 2*0.3 |

| Diesel automatic igniter (units) | 1 | 1 | 1 | 2 |

| Voltage (v) | 380 | 380 | 380 | 380 |

| Total machine weight (kg) | 1100 | 1300 | 1750 | 2200 |

| Dimensions (main unit + fan) – Length, Width, Height (cm) |

(200+100)*80*205 | (200+100)*80*200 | (253+120)*90*21 | (290+120)*100*220 |

Customer Case:

1:Vegetable Greenhouse, Swimming Pool, Hospital,Biochemical Engineering

2:Breeding Fram, Restaurant, Shampoo, Food Processing

3:Gym Factory, Distillery, Soybean Factory,Hotel

4:Factory Central Heating, Home Heating, Washing and Ironing, School

Our Advanrages:

About Us:

1. Our company has been established since 1991, with more than 33 years of manufacturing experience and 5 years of export experience.

2. Passed the GB/T19001idt ISO9001:2015 standard quality management system certification to ensure high quality and compliance with international standards.

3. Global boiler solutions, boiler design, order contracts, boiler delivery, boiler installation and commissioning service team.

4. So far, our products have been exported to 107 countries around the world with trustworthy quality and lifelong service.

![[GN:05003] Gemigliptin Impurity 3 (DP-IMP-3) [GN:05003] Gemigliptin Impurity 3 (DP-IMP-3)](https://tradedowntown.com/wp-content/uploads/2024/08/fbf45b7349c129991cecc4970bd37ee8-150x150.png)